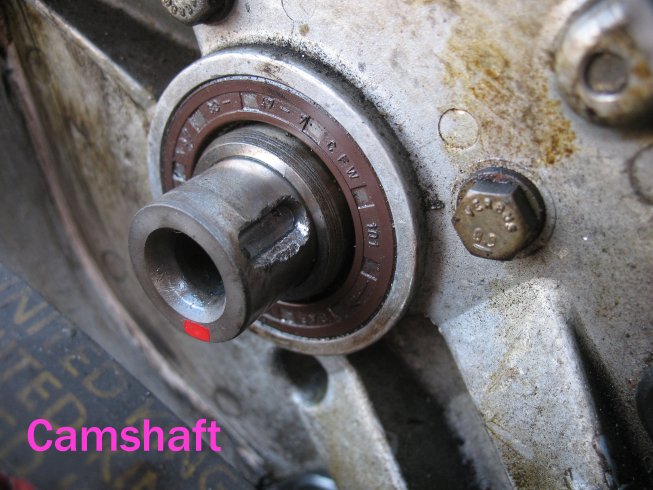

The Porsche 944 Cam Tower - Camshaft

November 15, 2009

Hmm, this does not sound good. Not at all.

November 16, 2009

I took off the distributor cap. This looseness is abby-normal.

I removed the rotor and the cheesehead bolt was loose enough to hand-untighten.

Yup, that's the problem. The bolt got loose then the gear got loose and chewed up the woodruff key and the cam gear keyway.

Oh noes, this does not look good!

I decided to get a used cam tower, the whole assembly. They are cheap, or at least cheaper then a replacement cam gear and camshaft.

November 20 & 21, 2009

Fuel Rail Removal

The Journey begins with a single snip!

Fuel Hoses get removed. I love the smell of petrol any time in the day. Four 10mm bolts hold the fuel rail down.

The fuel injector connectors do not plug in, they plug and snap in. You have to pull out the little wire clip to release them.

November 22, 2009

To remove the cam tower, you need a long 6mm and a short 6mm hex socket. I used Snap-on. I suggest you do as well. It would be a bummer to strip any of the bolts.

Luckily, they all came out without any problems.

You can use any old cheap 8mm hex socket or hex key for the bolt-cover things.

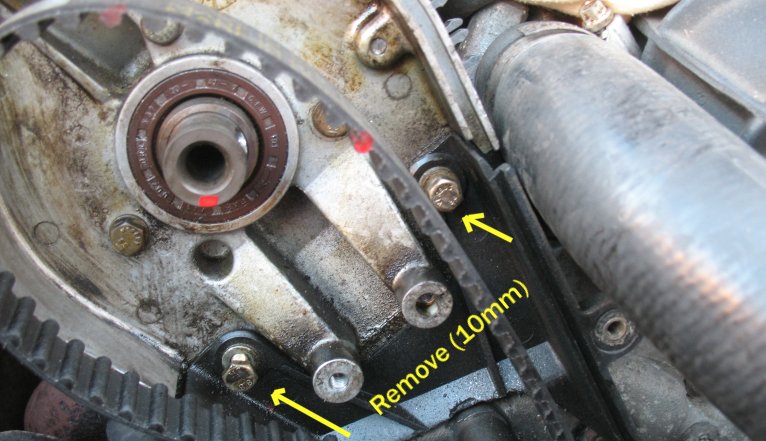

These two bolts come out.

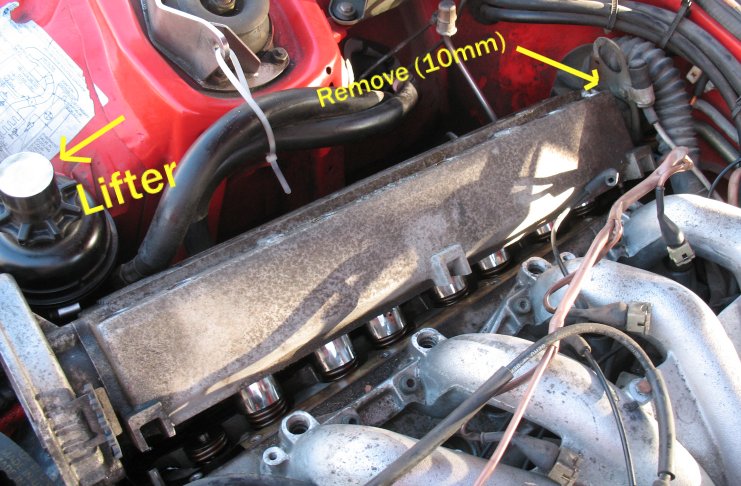

Once all the bolts are out the cam tower gets pushed up. The lifters can be removed. I removed one and perched it on the power steering cap. Don't forget to undo the little electrical do-dad bolted near the engine lift point.

Ta-da!

December 15, 2009

I had some difficulting finding the timing mark on the flywheel. With the help of a dowel in #1 spark plug hole, and also removing the electrial connector assembly obscuring the 'window', I was able to get it to TDC.

December 21, 2009

The gasket must be installed dry. Both surfaces should be perfectly clean and oil-free. I used a rag and acetone.

To install the inner hex bolts (six of them), I added a pair of magnets to either side of a 6mm t-handle hex wrench. The magnets get heat-shrink tubing on top to prevent them from falling off. Much less messy then using grease in the bolt-heads.

You have to be careful not to drop a bolt inside the cam housing. Dropping a single bolt could mean taking the housing off again. Work carefully!

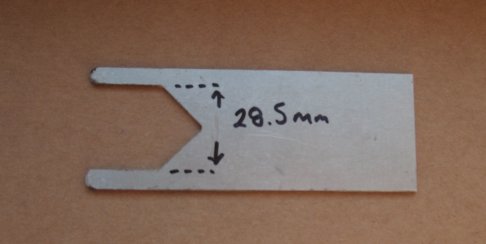

I made my own little belt tension wrench on my CNC mill. It was supposed to be 27mm, but I didn't properly account for the end mill thickness, so it turned out 1.5mm too large. But it worked fine. It's 0.076" thick (about 2mm).

December 27, 2009

Guessing at the belt tension

January 1, 2010

It's alive!

I started it up. Sounds good, no leaks detected, tappets are quiet enough

Now I have a new problem. My clutch slave cylinder has stopped working! I hear that happens when you let the car sit for a while. It's always something. Well, assuming it is the original part, it did give a quarter-century of service.

April 2010

After driving around for a few hundred miles, I only needed to:

- Tighten the 4 10mm fuel rail bolts (they had all come loose!)

- Tighten the hose clamp at the block near the heater valve (it was leaking)

No timing belt problems, no oil leaks from the cam tower.